EKO modular flue systems are characterized by high stability of construction. This allows erect our flues up to total height 25 m, measuring from base if their height above the surface of roof corresponds to values shown in Tab. 4.

| Type of flue | Diameter of flue (cm) | External dimensions (cm) | Height of flue h (m) | Brick finishing 12 cm (m) | Plastered 2cm (m) |

|---|---|---|---|---|---|

| one duct | 14-20 | 36x36 | 8 m | 2,10 | 1,50 |

| 8-25 m | 1,80 | 1,00 | |||

| one duct with 1 ventilating duct | 14-20 | 36x50 | 8 m | 2,40 | 1,70 |

| 8-25 m | 2,00 | 1,00 |

ATTENTION!

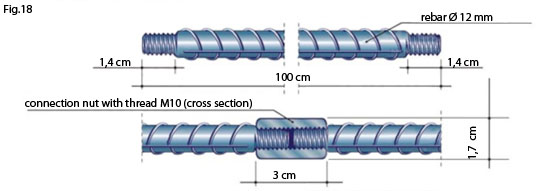

Precondition of applying of the table is support of sides of flue in the construction of roof of the building – Fig.17

In order to ensure horizontal stability of flue in the exit through roof and at the same time to insulate it from the construction of building, appropriate fastening of it in the construction of roof shall be carried out. Lattice enclosing flue shall be formed from square pipe or c-profile and it shall be fastened with help of screws to beams of roof construction. Fasten metallic lattice above or below the beams. Height of above roof part of flue h according to Tab. 4

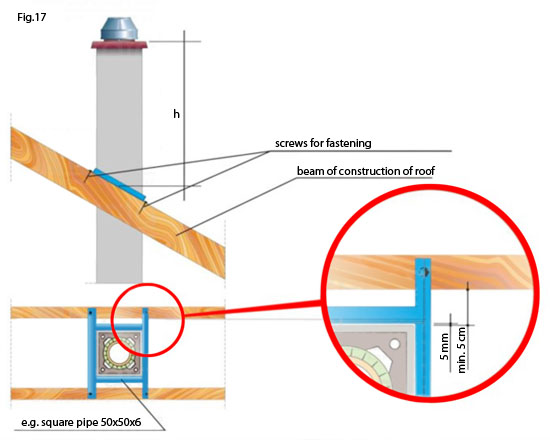

Above roof parts of EKOmds flues, which exceed values specified in Tab. 4. Reinforcement is formed from metallic rebars ∅12 mm, which are placed in Ø 30 mm openings situated in corners of modular block. In order to make reinforcement process easier, it is recommended to use rebars Ø 12 mm with threaded ends and connect them with each other with long nuts with inside thread M10 mm – Fig.18

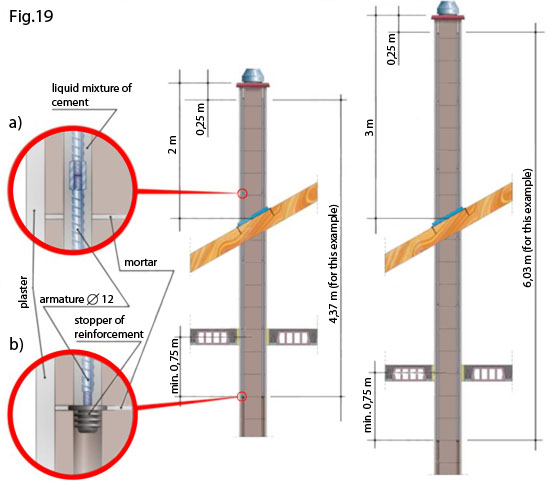

Standard length of rebar is 100 cm. After the placement of the amount of rebars necessary for the specific flue, the last rebar shall be tailored so that its upper end is about 25 cm lower than the end of flue. Rebars shall be supported on special stoppers, which are stuck in advance in openings placed in corners of the flue block at the corresponding height – Fig.19.b The recommended total length of reinforcement should be twice as great as the length of above roof part of flue (e.g., for flue with 2 m above roof part – 4 m; 3 m – 6 m reinforcement) and below it should be supported in the distance at least 0,75 cm under the ceiling – Fig. 19

Openings situated in corners of modular blocks, in which rebars are stuck and connected with each other, shall be filled with liquid mixture of cement – Fig.19.a